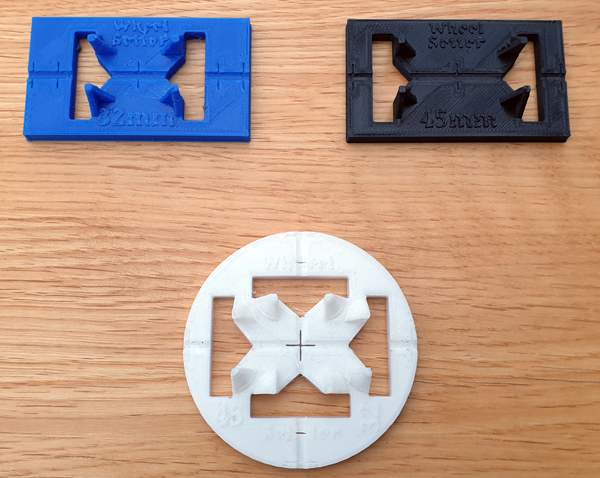

32/45mm Chassis

32/45mm Chassis |

2-Plank Wagon |

5-Plank Wagon |

Tank Wagon |

Coach New SWB |

Industrial Chassis |

Industrial Flatbed |

Industrial Snow Plough |

Industrial Brake Van |

Wire Cutters/Snips (Flush) |

Diamond Files |

Locking C-Clamp |

Clamps |

|

Glue Application

I use an application pattern similar to this when affixing large flat pieces together such as the chassis & bed on the industrial wagons or inner & outer side halves. This allows for a good glue coverage but minimizes the risk of air bubbles being trapped between the surfaces. |

Step 1.

Using a sharp craft knife or diamond file you can remove the excess material from the lip of the hole and slightly chamfer the entrance. |

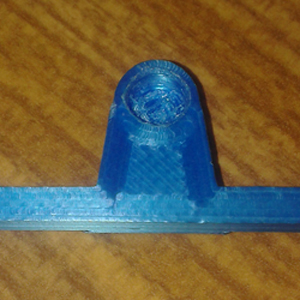

Step 2.

Seat the bearing in the mouth of the hole as level as possible. As you can see, the hole has been prepared/enlarged so the bearing is snug but not overly tight. |

Step 3.

Use a set of C-Clamp grips to ensure an even pressure and gently ease the bearings into place. Be careful! - too much pressure could damage the plastic or the bearing, you can aid the pressing home with a trace of oil if you wish. |

Step 4.

The bearing face should finish flush with the plastic. |